|

NEW COMPACT 16-TRACK, 2-INCH RECORDER/RFPRODUCER NEW COMPACT 16-TRACK, 2-INCH RECORDER/REPRODUCER

C. Dale Manquen, Electronic Engineer

Mincom Division Minnesota Mining & Manufacturing Company

300 South Lewis Road Camarillo, California 93010

Presented at the 35th AES Convention October 1968 in New York

ABSTRACT

The use of a single electronics housing to hold 16 tracks of record and reproduce electronics has permitted the construction of a two inch recorder/reproducer that is as small as a normal four track machine. The system features full remote operation, high strength construction, and a new capstan drive method that sets a new standard in timing accuracy.

GENERAL

The current trend in master recording has been to utilize an ever-increasing number of recorded tracks to add versatility to the recording process. Eight track machines using one inch wide tape have become a common tool in the studio, but the limitations of eight tracks have spurred a demand for even more channels of -recorded information. Since the transition to eight track was somewhat painful, an analysis of the trouble- some areas was in order before embarking on a new program which might have the same pitfalls. Experience shows that the rising cost of operating errors caused by carelessness, confusion, and fatigue justify a great deal of effort to make the operation of multitrack machines both rapid and straightforward. The design effort requires a great amount of human engineering before any electrical or mechanical engineering can be undertaken. Some of the factors that must be considered are the intelligibility of multiple meter displays, methods of input/output monitor selection, location of Re6ord/Safe/Syne selectors, and the accessibility of components and wiring for calibration and maintenance. The physical size of the machine has a direct beating on its portability and its interchangeability with present eight track recorders. The fact that-it must fit through a 30 inch door is not a license to take more space than is absolutely necessary. Smaller machines tend to be more rugged and thus require less maintenance. Once the above considerations have been combined to yield a physical package, the real engineering can begin. The transport problems that must be overcome to handle ten-pound reels of tape smoothly can be quite tricky. The vibrations and dynamic loads that are developed by an unbalanced reel in fast modes can shake a machine to pieces. Since wide tape is very prone to trap an air blanket between the layers of tape, high power reel motors must be used to keep the winding tensions high in fast forward and rewind. The stubborn behavior of wide tapes when any steering or guiding is attempted requires accurately aligned components that are rigid enough to resist high loads. The capstan and its drive system must have very little speed variation to permit splicing segments from both ends of a reel with- out any pitch change. The ways that the above problems can be resolved are as numerous as the engineers who tackle them. The following description covers one approach to the problem.

DESIGN COALS OF THE SYSTEM

The system to be considered here is the combination of a 3M Isoloop audio tape transport equipped for two-inch wide tape and a sixteen track record/playback electronics package. The overall size is less than 30 inches square by 5 feet high. Full remote control has been provided with special attention being paid to making the operation simple and dependable. The performance specifications are generally the same as the present 3M C-401 recorders with some improvements. In addition, the C-401 printed circuit cards are utilized to make the machine more compatible with existing equipment. The basic console and transport are essentially identical to the current versions. The transport is pivot mounted in the top of a rectangular plastic-laminated wood console. Below the transport is mounted a single electronics package which is 24 inches wide by 21 inches high. The meter display panel is mounted above the transport on metal risers. The system is completed by the addition of a self-contained power supply in the lower rear of the console and a remote control cable on the end of a 25 foot cable.

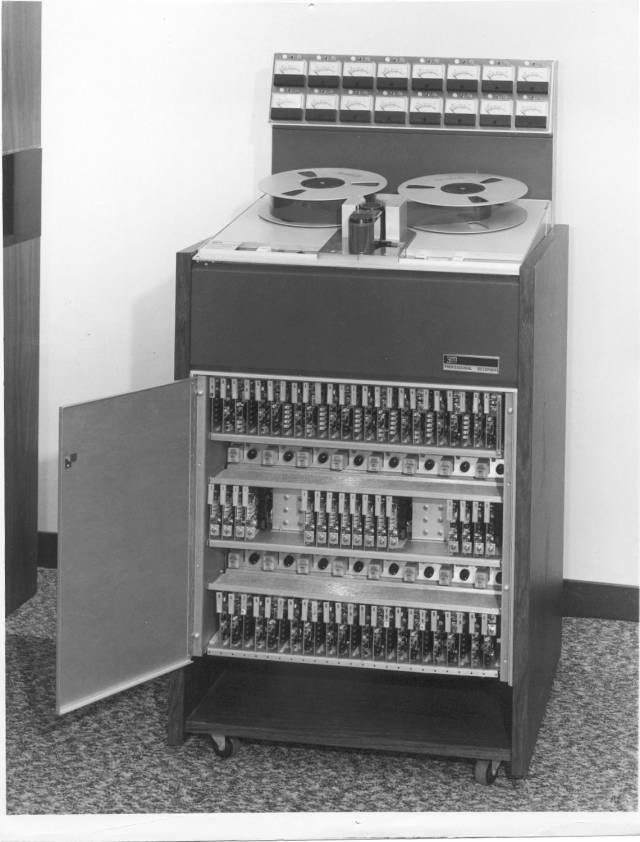

Model 56 Prototype Note single door, small casters, two erase capacitor mounting plates

REEL DRIVE SYSTEM

One of the biggest problems that was encountered in the design of the two-inch transport was the reel drive system. It was known at the outset that the reel motors that are used on transports employing one-inch tape would not be adequate to handle the heavier two-inch tape. Various planetary reduction systems were considered, but the final choice was to use direct drive supplied by a motor with two and one-half times the conventional motors output. Since the two inch transport is intended for horizontal operation only, the reel hub that has been designed has no locks or holddown mechanism. It would indeed be very difficult to force ten pounds of reel and tape to do anything but stay in place. A new feature is that the hub height may be easily adjusted by a hex head screw that is accessible from the top of the hub.

During this work, it was noted that some criterion for the measurement of the relative packing tension on a reel of tape was needed. The wide tape tends to trap an air blanket during high speed operation which leads ~ to a very loosely wound tape. The result is that what started as one reel of tape now becomes "one plus" reels of tape. One way of measuring the relative packing density is to measure the compression at the outside of the reel that is produced when a force of 16 ounces is exerted radially inward. A maximum deflection of 1/16 inch for a 3600-foot reel was considered to be tight enough to prevent any damage due to handling.

The reel control logic is unchanged from current machines, but some of the component values were altered to suit the larger motors. The maximum rewind and fast forward speeds have been reduced to help contro1 the air blanket. This loss in speed increases the rewind time for a 3600-foot reel from 90 seconds for a one-inch machine to 160 seconds for a two-inch version.

The problem of reels for two-inch tape deserves some consideration at this point. The normal audio reels consist of two flanges of .050 inch aluminum mounted on a loose-fitting hub. The nominal clearance between the flanges and the tape edges is typically .100 inch. In addition to protecting the edges of the tape, the flanges also provide some guiding of the tape in fast modes when the air blanket allows the tape to slide from side to side on the winding reel.

Handling of two inch tape on normal audio reels has shown the normal flange to be too weak to protect the tape. Permanent deformation may result from just lifting a reel by its top flange. For this reason, the two inch transport has been designed to use the semi-precision reels that are commonly designated "video reels". The .090 inch thick flanges of these reels are accurately positioned by a shoulder machined into the hub. The improvements in runout and flange wobble that are possible with these reels greatly reduce the hazards to the tape. A side benefit is a great reduction in the-vibration due to reel imbalance at high speeds.

CAPSTAN DRIVE SYSTEM

The capstan drive system has undergone an extensive redesign. The normal rim-driven rubber tire flywheel has been replaced by a crowned flywheel that is linked to the motor by a polyester belt. The belt drive was used on very early 3M Professional Audio Recorders, but it suffered from two shortcomings. First, the polyester belt developed a static charge that attracts dirt that will cause flutter. This has been corrected by enclosing the drive system in a vacuum-formed plastic cover. The second problem was acoustic noise transmitted from the motor to the transport casting and thus radiated into the control room. A change in motor design has reduced the acoustic noise of a rigidly-mounted motor to a level below the noise of the present resiliently-mounted motor. The belt drive has very little low frequency flutter because the runouts of the machined metal parts can be controlled very tightly. Speed accuracy is determined by the tolerances on the drive members and thus requires no adjustment. The speed variation from beginning to end of reel is so small that there need be no concern when splicing sections from various parts of a reel. The resultant capstan speed drift from beginning to end of reel is typically .01%. Wideband flutter from .5 Hz to 5 KHz is a maximum of .075% when a tape is recorded and reproduced on the transport being tested.

The capstan and reel motor parameters determine the speed with which the tape may be started in the play mode. Starting loops have been completely eliminated by using the capstan to accelerate the tape smoothly. The capstan motor is stopped in normal standby and fast modes. When the PLAY button is pressed, both pressure rollers engage simultaneously and the capstan motor is started. This technique achieves stable tape motion in less than one second at any point in the reel. When the STOP button is pressed, the rollers release and the capstan motor is braked by a pulse of direct current. An interlock prohibits the reengagement of the PLAY mode for two seconds to ensure that the capstan has stopped.

HEAD MOUNTING PLATE

Another component requiring major changes is the head mounting plate. Provisions have been included on all transport castings for a second head cable connector plug, but head mount plates suitable for up to eight tracks had mounting tabs for only one plug. The new plate is enlarged to accommodate a second plug and also strengthened to twice the previous load-bearing capability. Both the record head and the reproduce head have hum shields and variable azimuth adjustments. Particular attention has been given to minimization of head vibration since this can result in resonant peaks in the flutter spectrum.

SIGNAL ELECTRONICS PACKAGE

The signal electronics package is a much more radical departure from the present design than is the transport. The major assembly of this package is a card cage that houses 64 printed circuit cards. Overall module size is 21 inches high by 24 inches wide by 12 inches deep.

The front of the module is covered by two doors that open to allow access to all of the cards and control components. The rear of the module, which holds the input/output transformers and connectors, is split horizontally to permit access to the internal wiring. Inside the module are three rows of printed circuit cards and two rows of control components. The top and bottom rows of 24 cards each contain eight tracks of record and playback cards grouped by track sequence rather than function. The center row houses all 16 tracks of bias/erase amplifiers. In the two open spaces between the rows of cards are the control components. This area contains three relays per track for record, sync, and input/output monitor select; two potentiometers for input level control and sync level calibration; and two plug-in transistors for the relay logic circuits (see Figure 2.).

OUTPUT DISPLAY PANEL

The output display panel is mounted above the transport for easy viewing. Sixteen, 2-1/2 inch, VU.meters are employed. Human engineering dictates that two horizontal rows of eight meters each, mounted one above the other, provides most readily observable indications with a minimum of confusion. Each meter is numbered for ready channel identification. Above each meter are two indicator lamps and a spring-loaded toggle switch for input/output monitor selection. Pressing the switch to the left engages and holds the monitor relay to permit "A" or input monitoring. Pressure to the right releases the relay for "B" or playback monitor. This switching can be activated for all tracks simultaneously by using the master A/B buttons on the transport.

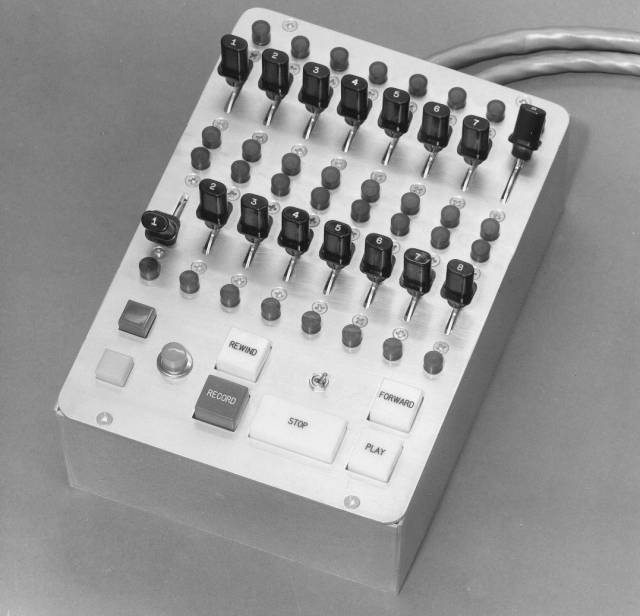

CONTROL BOX

The Record/Safe/Sync [1] controls and indicator lights are clustered on a remote panel that also houses a set of transport mode controls. This remote control assembly is supplied with 25 feet of cable to permit operation from a mixing console. The operation of a tape machine from the remote control box is similar to normal operation, but the box includes extra convenience features that are not possible without it. For example, the addition of a Normal/Cue program select switch allows two distinct sequences of-operation.

Prototype control panel with cardboard box.

Panel was parts of two 8-track panels Heli-arced together.

For normal operation, the control circuit will activate the Sync mode on any preset track only when the record mode is active on the transport. With this logic, after a selection has been recorded with some tracks in the Sync mode, the same tape can be replayed in the normal reproduce mode without resetting any switches. If a second recording attempt is necessary, starting the transport in RECORD will again activate the Sync mode on the previously selected tracks.

A common situation occurs where the above logic is not adequate. If it is desirable to listen to a prerecorded track for cueing purposes before the record mode is punched in, the "cue" position of the program select switch is used. This "cue" mode permits monitoring the Sync playback in RECORD, PLAY, or STOP. Since Sync is monitored in PLAY, it is not possible to obtain the instant playback from the reproduce head while using the cue program.

Both Normal and Cue are necessary to cover all possible conditions of operation. Remote control units that are currently in the field have demonstrated that this choice of programs is one of the most useful features included in the remote box. Very little time is required for operators to master its use.

Adequate high speed muting is provided in both 'normal" and "cue' because the Sync mode is deactivated in FAST FORWARD and REWIND.

POWER SUPPLY

With the exception of the transport logic, all signal and control circuits are driven by a common power supply. The power supply is a self- contained unit that is fastened to the floor of the console. The supply has short circuit current foldback limiting to allow continuous operation into a shorted load.

The module is protected from reverse voltage by a reverse biased diode connected in shunt with the incoming +28 volt power bus. This eliminates the impedance of a series diode for normal operation, but places a virtual short across any power supply that might accidentally be reversed during service or -replacement.

PLAYBACK PREAMP

The cards used in the new module are identical to the cards used in the current 3M machines. A brief description of each follows:

The playback preamp provides equalization and phase correction for two tape speeds. The first two of four direct-coupled stages provide tape head equalization with both high and low frequency adjustments. The next stage is a phase splitter that drives a phase rotation network that is relay switched to optimize both speeds. The final stage is an emitter follower to drive the level calibration controls. The +28 volt line is filtered by an active decoupler to provide minimum loss and thus ensure the maximum possible supply voltage for the phase splitter.

A small shielded transformer is also mounted on the playback preamp card. During Sync operation, this transformer steps up the playback voltage from the record head so that it can drive the preamp input at a level that is about equal to the normal playback head.

LINE AMPLIFIER

The line amplifier is a quasi-complementary circuit with heavy feedback loops. The transformer coupled 600 ohm output is capable of +28 dBm with less than 1% distortion from 30 Hz to 15 kHz.

The first stage is an emitter follower to drive the amplifier stage through a low impedance feedback network. The single class A stage supplies gain for feedback and for closed loop gain. The quasi-complimentary output transistors are capable of five watts continuous output. D.C. bias feedback ensures stable operation for a wide range of voltage and temperature.

RECORD AMPLIFIER

The record amplifier card contains a record amplifier and an input monitor preamplifier. The single stage monitor preamp provides sufficient level to drive the line amp to +14 dBm output at normal input reference levels.

The first stage of the record amplifier raises the signal level before insertion into an RC equalizer for high and low frequency boosts. This network is followed by a junction FET stage to limit the noise introduced by the high impedance equalizer network. The head driver is a Darlington amplifier feeding a series resistor for constant current operation in the record head. An adjustable diode network is included in the driver to compensate for third harmonic distortion as the tape nears saturation.

BIAS/ERASE AMPLIFIER

A common transformer that bridges the 120 kHz bias bus feeds the bias and erase amplifiers. The first stage of each of the independent amplifiers is a class A stage to supply drive to the push-pull output pairs. The output of the erase amplifier is coupled to the erase head by a variable capacitor tuned to resonate the circuit. The bias-amplifier is coupled through a bias level pot and an adjustable noise balance circuit. Test points are provided for monitoring both the bias and the erase currents.

MAINTENANCE

Although the problems of keeping 16 tracks operating properly at all times must be expected to be numerous, an effort has been made to keep servicing time to a minimum. The use of plug-in cards allows a relatively unskilled person to isolate and replace a defective circuit without a great loss of time. The number of cards in the current 3M eight track machine is 56, but modifications made possible by this new packaging technique require only 64 cards for sixteen tracks.

Even though all of the signal switching is now done by relays rather than switches, these -relays and their control transistors are replaceable from the front of the module. In the event that a replacement transistor is not available, removing a defective sync control transistor will disable Sync on a troublesome channel but will not hinder the RECORD mode. Removal on an A/B control transistor locks that track in the B or playback mode.

SUMMARY

The recorder described above has been designated the C-405 sixteen track recorder/reproducer. It and its companion C-402 sixteen track reproducer represent a first step into the expanding two-inch tape market.

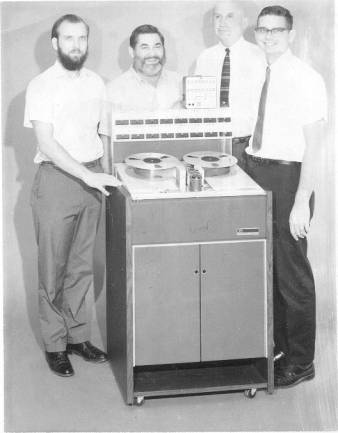

The author wishes to acknowledge the assistance of the other members of the team who made this development work possible; John Mullin - Manager - Professional Audio Lab, Don Kahn - Mechanical Designer, and Jim Leatherman, Electronic Technician.

M-56 Design Team

L-R Dale Manquen, Don Kahn, Jack Mullin, Jim Leatherman

[1] Sync denotes the use of a record head for playback purposes.