|

A WIDEBAND TAPE AND TRANSPORT DIAGNOSTIC METHOD A WIDEBAND TAPE AND TRANSPORT DIAGNOSTIC METHOD

Dale Manquen

Altair Electronics

1694 Calle Zocalo

Thousand Oaks, CA 91360

Originally presented at the 66th AES Convention May 6-9, 1980 Preprint #1637

Several changes incorporated February 2002

ABSTRACT

An analog magnetic tape recorder introduces more types of distortion into music recordings than any other component in the signal chain. An impressive array of instrumentation devices and standards have been developed for measuring electronic circuitry (THD, IM, SID, noise weighting filters, etc.) but meaningful evaluations of the magnetic head-to-tape interface have not received much attention. A new form of test instrument, a Tape and Transport Diagnostic System (T2DS), which measures both amplitude irregularities due to tape oxide non-uniformities and frequency deviations due to transport speed perturbations is herein described.

INTRODUCTION

A magnetic tape recorder introduces distortions to recorded material that are unique in the recording chain. Even if the recorder design engineer were able to completely remove all distortions from the record and reproduce amplifiers of the recorder, a broad range of distortions would still remain. Only one small portion of these distortions has been studied to any extent - conventional low-band flutter - but even this standardized measurement has been corrupted by the introduction of 'weighted flutter', a virtually useless specification when dealing with the critical evaluation of professional equipment. A more comprehensive method of measuring all of the sidebands or spurious frequency components created by amplitude and frequency modulations introduced at the magnetic tape-to-head interface is discussed herein and the effects will be demonstrated in the presentation.

Sideband Related Distortions

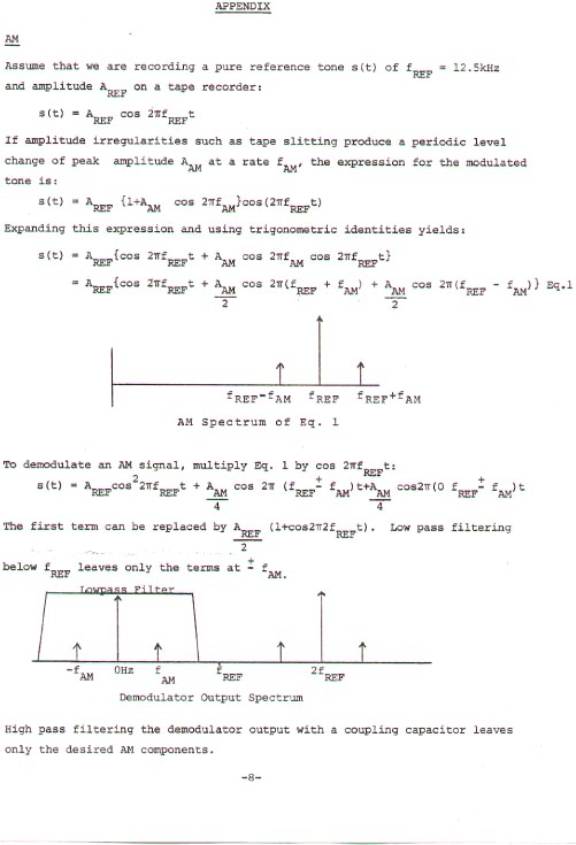

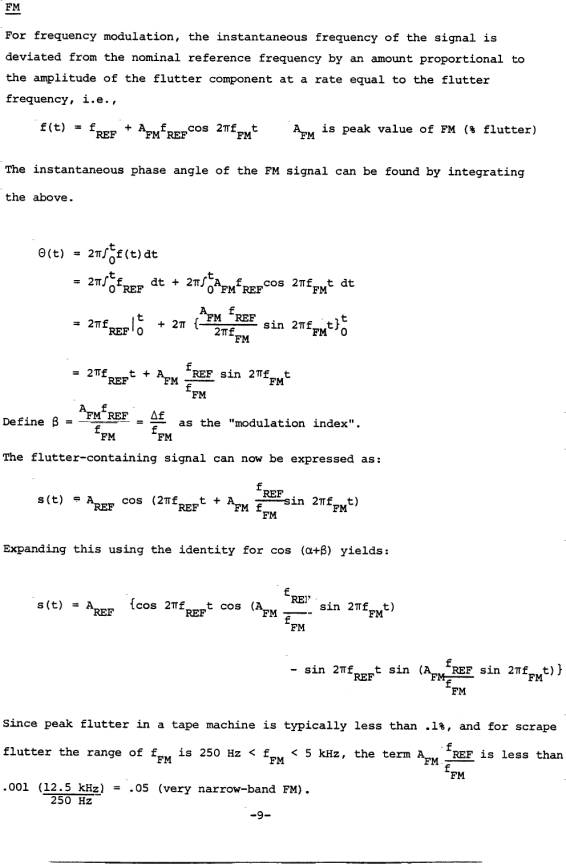

Contrary to your local audio equipment salesman's opinion, magnetic tapes and tape recorders are not perfect. Magnetic tapes suffer from dropouts, magnetic dispersion anomalies, poor slitting, and surface roughness; recorders contain eccentric rotating components, defective bearings, torque and speed variations in drive motors, and even scraping of 'rough' tape surfaces against stationary components. As shown in the Appendix of the original preprint of this article, all of the above imperfections create extraneous or sideband frequencies added to the normal musical content of a recording. Unlike some other forms of distortions, these new frequencies are not at all musically or harmonically related to the desired musical program. In fact, these sidebands are extremely obvious and objectionable but yet also difficult for even a trained listener to identify. Perhaps the reason of this apparent contradiction between perception and identification is that natural phenomena are usually linear operations that do not produce these sideband structures. Thus, when such components do occur, whether in a recorder or in a special effect for a science fiction movie, the listener responds quickly to the 'unnatural' sound, but is unable to identify the cause or source.

Wideband Flutter

A good starting point for this discussion is the well known but little understood 'flutter meter'. This device measures speed variations that produce frequency shifts (perceived as pitch changes) of the musical tones in a recording. Since the amplitude of these shifts is on the order of .1%, the change is only about 1/60th of a halftone. The listener does not perceive this error as a pitch shift, but he does respond to the extra components created at the music frequency plus and minus the frequency of the flutter component. As an example, a pure A440 note in the presence of a 120 Hz flutter would actually consist of a strong component at 440 Hz and two weak components at 320 Hz and 560 Hz. (Additional components of diminishing amplitude are also present at 120 Hz intervals from 440 Hz.) These new components 'broaden' the perceived tone or make it sound 'fuzzy'.

If the flutter rate is very low - less than a few Hertz - the listener can actually follow the pitch change. This effect is called 'wow' (pronounced as an Indian pow-wow.) At slightly higher flutter rates of 5 Hz to 50 Hz, the effect is so fast that the listener observes a 'fluttering' of the tone. Above approximately 50 Hz the listener responds to the sidebands as 'fuzziness'.

The upper frequency limits for flutter created by mechanical components are primarily a function of rotational rates of the balls inside ball bearings and the torque pulsation rates at even harmonics of the power line frequencies. A typical limit that is embodied in the NAB and IEC flutter standards is a lowpass function cutting off at approximately 250 Hz.

Unfortunately, tape recorders are not taught that they cannot possess flutter components above 250 Hz. On the contrary, the flutter spectrum extends throughout the normal audio spectrum! The source of the high frequency or 'scrape flutter' components is not mechanical rotations, but rather scraping of the tape surface against stationary heads and guides. The tape - an elastic filament under tension - vibrates at frequencies determined by the density, modulus of elasticity, tension, and 'length of free span' of the tape. A following detailed consideration of each of these factors may aid the reader in diagnosing scrape flutter problems.

The density of the tape is really the mass per unit length determined by:

1. The 'recipe' used to mix the magnetic oxide/binder system that is coated onto the polyester backing,

2. The thickness of the coating,

3. The density of the polyester backing, and

4. The thickness of the polyester base.

Lower densities produce higher frequency scrape flutter components.

The modulus of elasticity of the tape is primarily determined by the base film material, but is modified by the elasticity of the magnetic coating. Long-play tapes have thinner backings which will vibrate at lower frequencies. Tensilizing or pre-stretching polyester base films nearly triples the modulus of elasticity. (The modulus of elasticity in the direction of the tape travel is usually different than the modulus across the width of the tape due to the anisotropic nature of extruded polyesters.)

The tension in the tape may vary from the beginning to the end of a reel. This can produce a change in the flutter spectrum throughout the length of a reel. Low tensions reduce the flutter frequencies and minimize the exciting frictional forces.

The length of free span is the distance between massive rotation elements (rollers) that are analogous to fixed supports on a vibrating string. These rotating elements must have enough inertia to absorb the vibrational energy of the tape as the vibration tries to move across the roller. The contact pressure on the roller must also be high enough to hold the tape firmly to the roller surface. As an example of the last condition, note that the large inertia roller on the left side of many older tape transports will actually generate scrape flutter while the roller is accelerating to operating speed - a condition lasting as logn as 15 seconds after the play mode is initiated. 'Scrape flutter idlers' are rollers that are inserted between the heads of a recorder to break the long free span of the tape from the supply reel to the capstan into shorter 'subspans'.

Another consideration is the magnitude of the exciting force. The frictional drag on the tape from sliding over stationary surfaces is a primary factor in determining the amount of scrape flutter excitation. A quick 'figure of merit' for comparison purposes can be calculated by measuring the angle of tape wrap around all of the stationary guides and heads between the supply reel and the capstan. The sum of all of these angles is proportional to the frictional drag. Good machine may have as little as 25o of wrap, but 'bad' machines may have 270o.

The roughness of the tape surface and guides and the affinity of the tape and guide materials also determine the frictional force present to excite scrape flutter. Very rough surfaces are raspy; ultra-polished tape surfaces may suffer from a stick/slip phenomenon that generates jerking as the tape repeatedly tries to stick to a surface and then is broken away to slide freely.

Occasionally recorders will 'invent' new ways to confound the designer. One such example is the squealing of rubber pinch rollers on various brands and types of tape. This squeal produces excessive scrape flutter that is permanently recorded on the tape as frequency modulation at the squeal frequency.

Guidelines for selecting low scrape flutter recorders are straightforward - pick a deck with

1. Few stationary surfaces and guides,

2. Small angles of wrap around the stationary guides,

3. Short spans of tape between rollers,

4. Low tape tension and

5. Servo-controlled D.C. motors.

Extra heads for alternate formats or bi-directional operation are detrimental if they are not isolated by a capstan. 'Closed loop' machines that have relatively short spans of tape locked to capstan surfaces at both ends of the head assembly provide very good performance if the tension is properly controlled.

Tape Related Sidebands

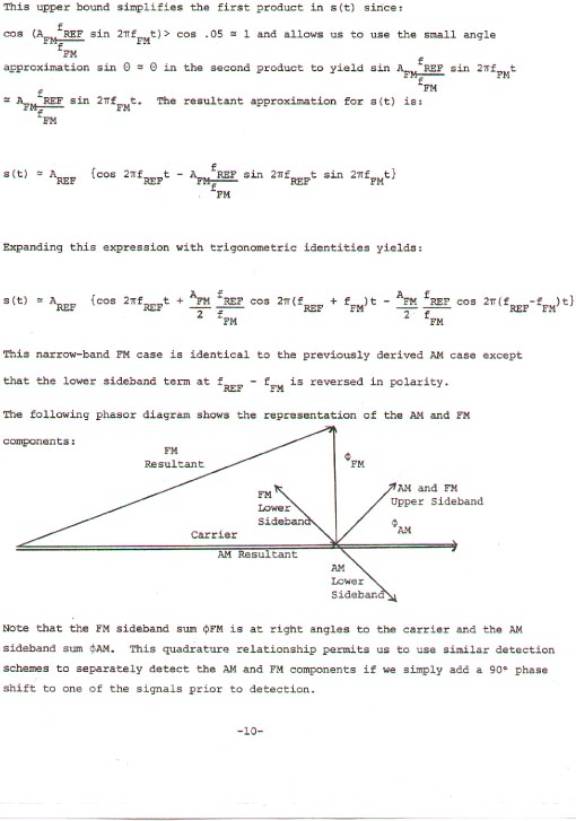

In addition to flutter-related sidebands, the magnetic recording process suffers from a host of sidebands resulting from amplitude variations due to tape imperfections. The sidebands created by these tape related amplitude modulation (AM) terms and narrowband FM flutter terms are similar in spectrum with the exception of the phase of the lower sideband. Since the ear is a 'spectrum analyzer' working in the frequency domain, we perceive AM and FM sideband similarly. The maintenance technician and designer, however, are keenly interested in the type and source of the sidebands. For example, reducing scrape flutter will not alleviate an AM sideband problem created by poor oxide dispersion on a tape specimen. Herein arises the need for a diagnostic tool that distinguishes between AM and FM sidebands. (The amplitude display of a spectrum analyzer cannot make this distinction since it contains no phase information.)

Before examining an instrument that fills this need, let us investigate the causes of AM sidebands. Tape is a mixture of oxide and glue smeared onto a sheet of plastic. A 'perfect' magnetic recording requires that the magnetic performance of a tape be identical at every point on the tape surface. This would imply on variation of the following:

1. Ratio of oxide to binder,

2. Magnetic property of each oxide particle

3. Thickness of the oxide layer,

4. Orientation of the oxide particles

5. Surface smoothness, and

6. Density of the oxide after calendering.

Additional problems related to the mechanical contact of the tape with the head are :

7. Poor slitting, including ruffled edges, 'country laning' or low frequency slitting undulations, and cupping of the tape across its width,

8. Worn heads with flat faces or 'horns' on the edges of non-undercut heads,

9. Inadequate wrap of the tape on the heads,

10. Racking error (gap not at the apex of wrap),

11. Zenith or azimuth errors making the tape ride up and slip down on the heads in jerks, and

12. Low tension.

All of these tape and transport problems produce a modulation envelope that creates amplitude errors in the music. The ear can easily detect the resulting AM sidebands.

The T2DS Approach

A diagnostic device to measure all of the sideband effects that have been described above would need to be capable of measuring any sideband created within the audio band. A practical limit arises, however, when trying to design a device that will measure the AM and FM content of a test tone. The recorder system must be capable of passing the upper sideband at the maximum modulation frequency of interest. Assume a 'safe' upper limit of 18 kHz for a professional recorder, and recognizing that Shannon's sampling theorem require a 'carrier' at twice the modulation frequency, a reasonable choice is a 12.5 kHz test tone and a demodulated bandwidth of 5 kHz

If no passband filter from 7.5 kHz to 17.5 kHz is used on the recovered tone from the recorder, 'alias' frequencies will be introduced into the measurement. Since these alias components are actually images of modulation products, they are retained in the T2DS processor and included in the quantitative measurement. (In reality, the scrape flutter content decreases as frequency increases due to mechanical dissipation in the tape. The contribution of flutter terms near 12.5 kHz is minimal.)

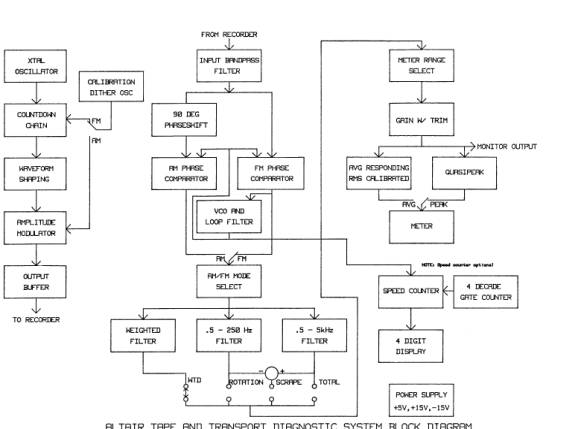

The T2DS block diagram in Figure 1 contains the following elements:

1. A 12.5 kHz crystal-controlled reference oscillator producing low residual AM and FM noise with built-in AM and FM calibration modes,

2. An AM demodulator,

3. A FM demodulator,

4. Selectable low-pass, high-pass, and weighting filters, and

5. Metering circuitry for average and peak measurements.

The system provides independent AM and FM measurements in the passbands of .5 Hz-250 Hz (mechanical components only), 250 Hz-5 kHz (scrape components only), and .5 Hz-5 kHz (all components combined). A weighting filter is included for conventional NAB and IEC weighted flutter measurements. Residual measurement noise for the widest bandwidth is typically .005%RMS for FM and .1% for AM, which is approximately 20 dB below the best transport and tape tested to date.

SUMMARY

The Altair Tape and Transport Diagnostic System permits far more critical analysis of magnetic recording systems than hitherto available in a single inexpensive instrument. In addition to many professional master recorder applications, the T2DS permits checking high-speed machines such as duplicator master and slave transports running at 32 times normal speed and analog instrumentation recorders.

As a magnetic tape evaluation and quality control device, the T2DS provides a convenient tape testing method that is exactly reproducible by both vendor and purchaser, permitting reproducible tape performance data to be sent from the user to the manufacturer for the first time.

Test results to date indicate a far more positive correlation with T2DS measurements and the subjective evaluations by trained listeners than is possible with conventional NAB/IEC flutter meters. Combining a 20-fold increase in flutter measurement bandwidth with the tools to evaluate wideband AM performance is indeed worthwhile!

ALTAIR T2DS

Tape/Transport Diagnostic System

When professional tape recorders were first introduced thirty years ago, only rotating tape drive components were checked for proper operation. In fact, fifteen years elapsed before the audio industry even recognized that scrape flutter was very important for "clean" tape recordings. Unfortunately, an additional fifteen years passed before the introduction of an inexpensive flutter meter that will measure scrape flutter. But now, with the Altair T2DS, we can easily measure flutter over a frequency range 20 times wider than the NAB/IEC Standards permit.

But that is just the beginning. Now we can also test the amplitude performance of magnetic tape! Check for dropouts, bad slitting, poor tape-to-head contact, modulation noise, and even poor oxide mixing and coating. Even the smoothness and lubrication of the tape surface can be evaluated.

THEORY OF OPERATION

The analog magnetic tape recording process introduces errors not found in electronic circuits--AMPLITUDE and FREQUENCY modulations. When a pure tone is recorded and reproduced, extraneous sideband frequency components are added to the original signal by transport and tape imperfections, producing a fuzziness or lack of clarity.

The T2DS circuitry not only measures these sidebands, but it also identifies whether speed changes or amplitude changes cause them. (Not even a $ 10,000 spectrum analyzer can do that!) By detecting "in- phase" and "quadrature" sideband components independently in the frequency band from .5 Hz to 5000 Hz (limited by the tape recorders response cutoff at 18 kHz), the T2DS unit presents a more complete picture of recorder and tape composite performance.

To permit comparisons with current published flutter specifications, the T2DS also includes measurement modes equivalent to the standardized weighted and NAB/IEC measurements, but using the new reference frequency of 12.5 kHz.

1694 Calle Zocalo---Thousand Oaks, Ca. 91360---(805) 529-2496 dmanquen@msn.com

SPECIFICATIONS

Oscillator

Crystal-controlled 12.5 kHz sinewave at -6 dBm (Note 1) with less than.001% residual FM and AM noise contribution in measurements.

Calibrate modes provide digitally derived 150 Hz square wave frequency or amplitude modulation of the test signal for meter self test.

Input Section

Input signal is 12.5 kHz ±1 kHz at -6 dBm (Note 1)

LED signal level indicators for correct input level (Cal) , High level, or Low level below muting threshold

AM readings require nominal -6 dBm level ± 1 dB for accurate readings

FM readings are accurate over an input range of -16 dBm to+14 dBm

Measurement Bandwidth (FM and AM)

Wideband measurement - .5 Hz to 5 kHz for combined rotational and scrape components

Upper bandpass - 250 Hz to 5 kHz to isolate high frequency components

Lower bandpass - .5 Hz to 250 Hz to isolate components due to rotating tape drive members

Weighted - IEC/ANSI bandpass peaked at 4 Hz. (This mode is included primarily for verifying specifications.)

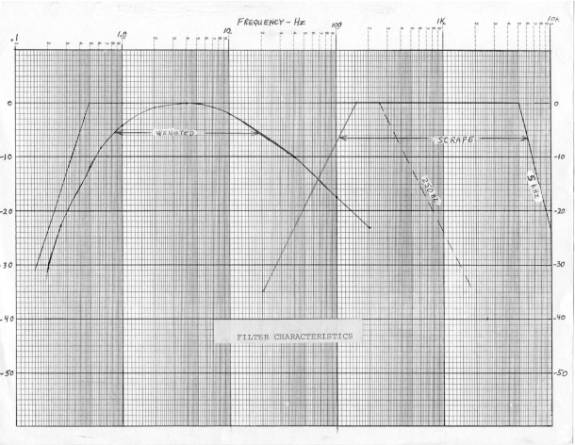

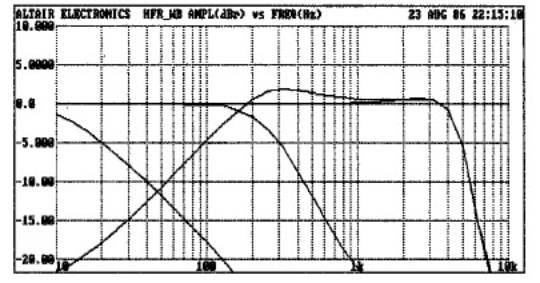

Flutter Measurement Bandwidths

Predicted response

Audio Precision plot of actual response

Meter Section

FM sensitivity - .01, .03, .1, .3, and 1% full scale

AM sensitivity - .1, .3, 1, 3, and 1 0% full scale

"Demod" output provides output signal after filters and meter range selection for oscilloscope, spectrum analyzer, and/or loudspeaker. Full scale meter deflection produces approximately.5V RMS.

Meter characteristics - selectable for either full wave rectified, average responding, RMS calibrated or quasi-peak.

"Slow" mode provides extra damping to slow erratic meter fluctuations.

Power

120V 50 or 60 Hz at 10 watts (240V optional)

Size

13.5 W x 3.75 H x 6.0 D (inches)

Note 1

The test level of -6 dBm into 600 ohms (.4V RMS) is 10 dB below normal "O VU" to avoid tape saturation of the test tone for 7.5 in/s recorders. Higher levels can be used at speeds above 7.5 in/s by raising the record level 10 dB and reducing the playback level sufficiently to light the "Cal" level indicator.

Note 2

This instrument is intended for testing high-quality recording equipment to its operating limit. Slow-speed recorders such as cassette decks that cannot record and reproduce a 12.5 kHz tone with good signal stability may exceed the 10% range of the AM section. Other versions of the T2DS that use 6.25 kHz or 25 kHz signals are available.

Note 3

Accurate speed or drift measurements can only be made with an accurate reference tape and a digital counter.